ATEX Zones Explained

ATEX Zones Explained

ATEX (ATmosphères EXplosibles) is a European directive that in part regulates the equipment and protective systems intended for use in potentially explosive atmospheres. ATEX zones are areas in which there is a risk of explosion due to the presence of flammable gases, vapours, or dust.

By classifying areas into different zones, the probability of an explosive atmosphere being present is known and steps can then be taken to prevent ignition sources from causing explosions. This includes the use of certified equipment and the implementation of safety procedures, such as limiting the use of electrical equipment, ensuring proper ventilation, and controlling potential sources of ignition.

ATEX Zones Classification

ATEX zones are classified into three categories:

Zone 0: An area in which an explosive atmosphere is present continuously, or for long periods or frequently.

Zone 1: An area in which an explosive atmosphere is likely to occur in normal operation occasionally.

Zone 2: An area in which an explosive atmosphere is not likely to occur in normal operation but, if it does occur, will persist for a short period only.

The classification of zones depends on the type and quantity of the substances present and the likelihood of an explosive atmosphere forming. Appropriate measures must be taken to prevent ignition sources from causing an explosion in these areas, such as the use of certified equipment and the implementation of safety procedures.

An atmosphere can become potentially explosive when it contains dangerous levels of flammable gases, mists, or dust. If a source of ignition is then introduced, combustion can occur.

ATEX Directives

Compliance with ATEX is mandatory for all equipment and protective systems intended for use in potentially explosive atmospheres in Europe and also used as a basis for hazardous area safety in many other regions. The aim is to ensure that such equipment is designed and manufactured to a high standard of safety and reliability, reducing the risk of explosions in potentially explosive atmospheres.

The risk of explosion can be reduced by preventing the release or build-up of flammable substances and by eliminating sources of ignition.

However, first, we need to understand if or how long an explosive atmosphere could be present.

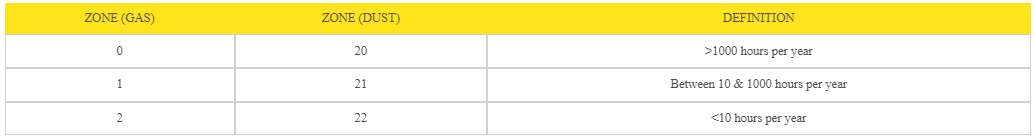

This is where zones are introduced and in general, this is based on historical information as per:

This table shows Zones in relation to Equipment Protection Levels that equipment is required to meet to ensure the correct level of protection is within a potentially explosive atmosphere.

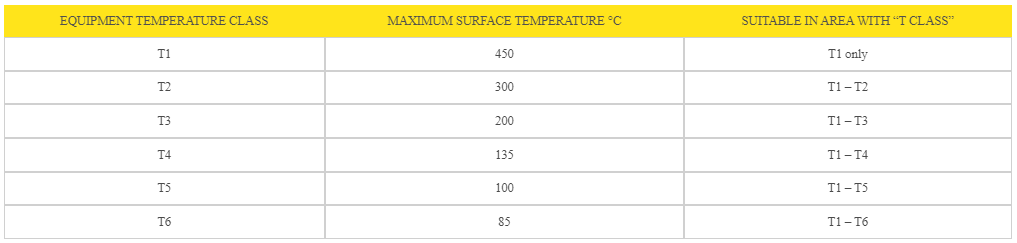

The following table shows Temperature Class, Max Surface Temperature (in normal & fault specific conditions) in relation to which Areas they are suitable for use.

Frequent-Asked Questions Around ATEX

– What does ATEX stand for?

ATEX is the abbreviation of the French “Atmospheres Explosibles”

– Are ATEX and IECEx the same?

ATEX directives are mandatory only to countries in the European Union but also used as a basis for hazardous area safety in many other regions whereas IECEx is accepted and /or mandated in multiple countries around the world. Members of the IECEx system are in Australia, Brazil, Canada, China, Croatia, the Czech Republic, Denmark, Finland, France, Germany, Hungary, India, Israel, Italy, Japan, Korea, Malaysia, the Netherlands, New Zeland, Norway, Poland, Romania, Russia, Singapore, Slovenia, South Africa, Sweden, Switzerland, Turkey, UK, USA, UAE.

– What types of industries are affected by ATEX Directives?

Industries that handle or store flammable substances, such as oil and gas, chemicals, pharmaceuticals, and food and beverage production, can be typically subject to ATEX regulations.

– What is the difference between an ATEX directive and an ATEX standard?

The ATEX directive sets out the legal requirements for equipment and protective systems intended for use in potentially explosive atmospheres. There are no ATEX Standards. The standards that provide guidance on how to comply with the directive are the suite of explosive atmosphere EN 60079 standards.

– What kind of equipment needs to be ATEX certified?

Equipment that is used in potentially explosive atmospheres, including electrical and mechanical equipment, must be certified as ATEX compliant to ensure that it meets the Essential Health and Safety Requirements (EHSRs) mandated within Europe.

– Who is responsible for ensuring compliance with ATEX Directives?

Employers are responsible for ensuring that their workplaces are safe and comply with ATEX directives. This includes implementing the necessary safety measures and ensuring that equipment is properly certified.

– ATEX vs NEC vs IECEx?

ATEX is generally a requirement in Europe, NEC is generally for the USA, and IECEx is generally recognized internationally. The IECEx system was established in 1995. Currently, member committees from 33 countries work within the framework of this system.

ATEX (ATmosphères EXplosibles) is a European directive that in part regulates the equipment and protective systems intended for use in potentially explosive atmospheres. ATEX zones are areas in which there is a risk of explosion due to the presence of flammable gases, vapours, or dust.

By classifying areas into different zones, the probability of an explosive atmosphere being present is known and steps can then be taken to prevent ignition sources from causing explosions. This includes the use of certified equipment and the implementation of safety procedures, such as limiting the use of electrical equipment, ensuring proper ventilation, and controlling potential sources of ignition.

ATEX Zones Classification

ATEX zones are classified into three categories:

- Zone 0: An area in which an explosive atmosphere is present continuously, or for long periods or frequently.

- Zone 1: An area in which an explosive atmosphere is likely to occur in normal operation occasionally.

- Zone 2: An area in which an explosive atmosphere is not likely to occur in normal operation but, if it does occur, will persist for a short period only.

The classification of zones depends on the type and quantity of the substances present and the likelihood of an explosive atmosphere forming. Appropriate measures must be taken to prevent ignition sources from causing an explosion in these areas, such as the use of certified equipment and the implementation of safety procedures.

An atmosphere can become potentially explosive when it contains dangerous levels of flammable gases, mists, or dust. If a source of ignition is then introduced, combustion can occur.

ATEX Directives

Compliance with ATEX is mandatory for all equipment and protective systems intended for use in potentially explosive atmospheres in Europe and also used as a basis for hazardous area safety in many other regions. The aim is to ensure that such equipment is designed and manufactured to a high standard of safety and reliability, reducing the risk of explosions in potentially explosive atmospheres.

The risk of explosion can be reduced by preventing the release or build-up of flammable substances and by eliminating sources of ignition.

However, first, we need to understand if or how long an explosive atmosphere could be present.

This is where zones are introduced and in general, this is based on historical information as per:

ZONE (GAS) | ZONE (DUST) | DEFINITION |

|---|---|---|

0 | 20 | >1000 hours per year |

1 | 21 | Between 10 & 1000 hours per year |

2 | 22 | <10 hours per year |

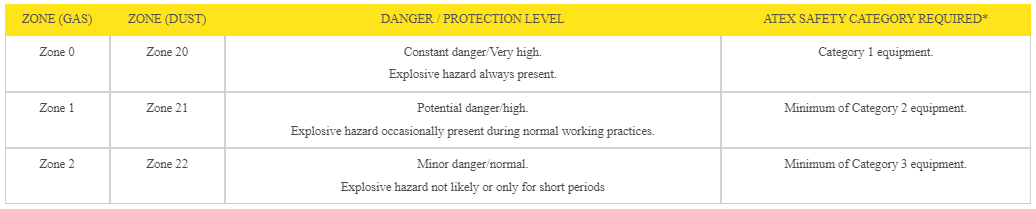

The following table shows Zones in relation to ATEX safety categories that equipment is required to meet to ensure the correct level of protection is applied within a potentially explosive atmosphere;

ZONE (GAS) | ZONE (DUST) | DANGER / PROTECTION LEVEL | ATEX SAFETY CATEGORY REQUIRED* |

|---|---|---|---|

Zone 0 | Zone 20 | Constant danger/Very high. Explosive hazard always present. | Category 1 equipment. |

Zone 1 | Zone 21 | Potential danger/high. Explosive hazard occasionally present during normal working practices. | Minimum of Category 2 equipment. |

Zone 2 | Zone 22 | Minor danger/normal. Explosive hazard not likely or only for short periods | Minimum of Category 3 equipment. |

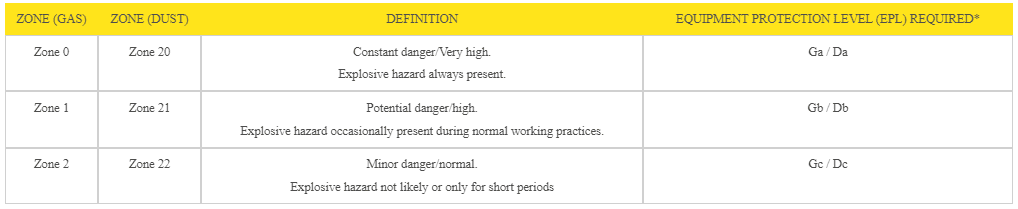

This table shows Zones in relation to Equipment Protection Levels that equipment is required to meet to ensure the correct level of protection is within a potentially explosive atmosphere.

ZONE (GAS) | ZONE (DUST) | DEFINITION | EQUIPMENT PROTECTION LEVEL (EPL) REQUIRED* |

|---|---|---|---|

Zone 0 | Zone 20 | Constant danger/Very high. Explosive hazard always present. | Ga / Da |

Zone 1 | Zone 21 | Potential danger/high. Explosive hazard occasionally present during normal working practices. | Gb / Db |

Zone 2 | Zone 22 | Minor danger/normal. Explosive hazard not likely or only for short periods | Gc / Dc |

EQUIPMENT TEMPERATURE CLASS | MAXIMUM SURFACE TEMPERATURE °C | SUITABLE IN AREA WITH “T CLASS” |

|---|---|---|

T1 | 450 | T1 only |

T2 | 300 | T1 – T2 |

T3 | 200 | T1 – T3 |

T4 | 135 | T1 – T4 |

T5 | 100 | T1 – T5 |

T6 | 85 | T1 – T6 |

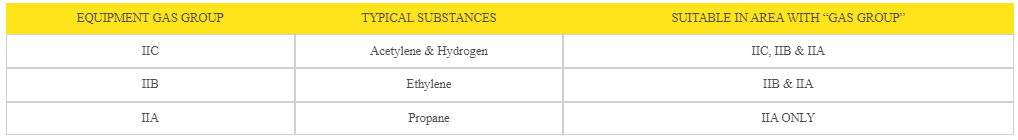

The following table shows Gas Sub Groups for surface industries, their example/typical substance in relation to which “gas areas” they are suitable for use;

EQUIPMENT GAS GROUP | TYPICAL SUBSTANCES | SUITABLE IN AREA WITH “GAS GROUP” |

|---|---|---|

IIC | Acetylene & Hydrogen | IIC, IIB & IIA |

IIB | Ethylene | IIB & IIA |

IIA | Propane | IIA ONLY |

Frequent-Asked Questions Around ATEX

– What does ATEX stand for?

ATEX is the abbreviation of the French “Atmospheres Explosibles”

– Are ATEX and IECEx the same?

ATEX directives are mandatory only to countries in the European Union but also used as a basis for hazardous area safety in many other regions whereas IECEx is accepted and /or mandated in multiple countries around the world. Members of the IECEx system are in Australia, Brazil, Canada, China, Croatia, the Czech Republic, Denmark, Finland, France, Germany, Hungary, India, Israel, Italy, Japan, Korea, Malaysia, the Netherlands, New Zeland, Norway, Poland, Romania, Russia, Singapore, Slovenia, South Africa, Sweden, Switzerland, Turkey, UK, USA, UAE.

– What types of industries are affected by ATEX Directives?

Industries that handle or store flammable substances, such as oil and gas, chemicals, pharmaceuticals, and food and beverage production, can be typically subject to ATEX regulations.

– What is the difference between an ATEX directive and an ATEX standard?

The ATEX directive sets out the legal requirements for equipment and protective systems intended for use in potentially explosive atmospheres. There are no ATEX Standards. The standards that provide guidance on how to comply with the directive are the suite of explosive atmosphere EN 60079 standards.

– What kind of equipment needs to be ATEX certified?

Equipment that is used in potentially explosive atmospheres, including electrical and mechanical equipment, must be certified as ATEX compliant to ensure that it meets the Essential Health and Safety Requirements (EHSRs) mandated within Europe.

– Who is responsible for ensuring compliance with ATEX Directives?

Employers are responsible for ensuring that their workplaces are safe and comply with ATEX directives. This includes implementing the necessary safety measures and ensuring that equipment is properly certified.

– ATEX vs NEC vs IECEx?

ATEX is generally a requirement in Europe, NEC is generally for the USA, and IECEx is generally recognized internationally. The IECEx system was established in 1995. Currently, member committees from 33 countries work within the framework of this system.

Want to learn more about potentially explosive atmospheres?

Americas

1225 North Loop West, Suite #705 Houston, TX 77008 Office: 713.862.0088 Fax: 832.358.1165

UAE

India

Myanmar

Thailand