Description

CMP TMC2X Cable Gland Technical Info

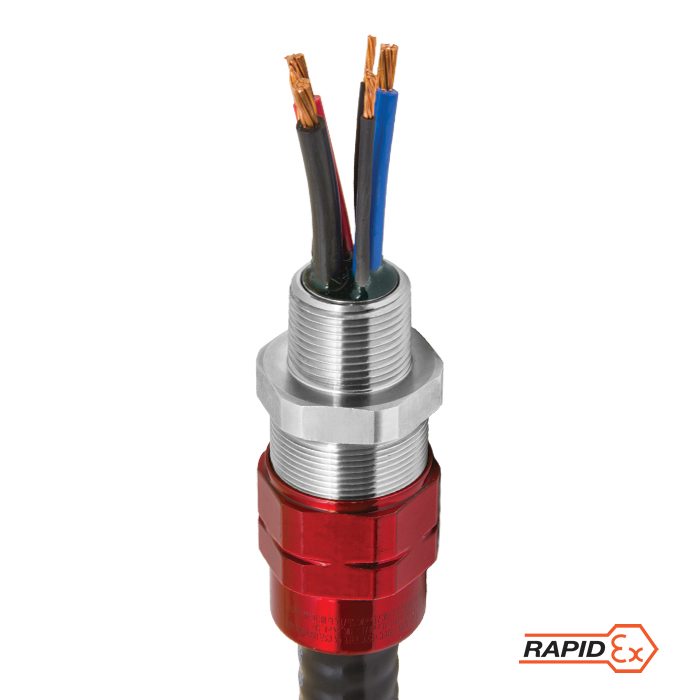

A CMP TMC2X barrier cable gland is used to terminate metal-clad (MC and MCHL) corrugated interlocked aluminum or steel cables as well as continuously welded armor (TECK) cables in hazardous locations. It utilizes a RapidEx high-speed liquid resin sealing compound, which forms a watertight mechanical connection while providing ground continuity.

This cable gland type is certified by ATEX for safe glanding in Class 1, Division 1, and 2, environments. It’s manufactured to meet a wide array of standards, specifications, and codes.

ATEX Certificates

- CML 18ATEX1336X

Compliance Standards

- IEC 60079-0,1,7,31

Approvals

- LRS: 01/00172

- DNV: TAE00000Y

- ABS: 20-LD1948801-PDA

- BV: 43180/A1BV

IECEx Certificates

- IECEx CML 18.0193X

Code of Protection

- Class I, Div. 1, 2, Groups A, B, C, D; Class II, Div. 1, 2, Groups E, F, G; Class III, Div. 1, 2

TMC2X cable glands feature a compact profile and 360-degree grounding pin. A simple, sequential installation process improves reliability while minimizing risk, cost, and setup time.

Available construction materials include brass, electroless nickel-plated brass, stainless steel, and aluminum constructions. EUTEX International’s standard offering is nickel-plated brass. Optional accessories include locknuts, earth tags, serrated washers, entry thread seals, shrouds, and ingress discs.

This cable gland is designed to excel in operating conditions from -76°F, or -60°C, to 185°F, or 85°C. With an extensive operating range, TMC2X cable glands can support many applications.

- Aerospace

- Defense

- Chemical

- Mining

- Minerals & Metals

- Commercial Construction

- Downstream Hydrocarbons

- Food & Beverage

- Industrial Energy

- Onsite Utilities

- Industrial Machinery

- Laboratory and R&D

- Life Sciences

- Medical

- Marine

- Oil & Gas

- Packaging

- Power

- Pulp & Paper

- Textiles

- Water & Wastewater

Here For You

EUTEX International is an ISO 9001:2015-certified supplier of electric cables and accessories for industrial use. We’re dedicated to providing quality products to clients with superior customer service.

Multiple locations worldwide enable our team to deliver the electrical products you need on time and within budget.

Give us a call for more information about the TMC2X cable gland. Our experts are standing by to answer your questions.

Technical

| Design Specification | BS 6121:Part 1:1989, IEC 62444, EN 62444 |

| Mechanical Classifications* | Impact = Level 8, Retention = Class D |

| Enclosure Protection | IK10 to IEC 62262 (20 joules) Brass & Stainless Steel only |

| ATEX Certificate | SIRA09ATEX1165X |

| Code of Protection | II 2G 1D, Ex d IIC, Ex e IIC Gb, Ex ta IIIC Da |

| Compliance Standards | EN 60079-0,7, EN 61241-0,1 |

| IECEx Certificate | IECEx SIR 09.0069X |

| Code of Protection | Ex d IIC Gb, Ex e IIC Gb, Ex ta IIIC Da |

| Compliance Standards | IEC 60079-0,1,7,31 |

| cCSAus Certificate | 2194053 |

| CSAus Code of Protection | Class I, Div 1 and 2, Groups A, B, C and D; Class II, Div 1 and 2, Groups E, F, and G; Class III, Div 1 and 2; Encl. Type 4X. Class I, Zone 1, AEx d IIC; AEx e II; AEx ta IIC: |

| cCSA Code of Protection | Class I, Div 1 and 2, Groups A, B, C and D; Class II, Div 1 and 2, Groups E, F, and G; Class III, Div 1 and 2; Encl. Type 4X. Ex d IIC; Ex e II: |

| Compliance Standards | CAN/CSA-C22.2 No 0-M91, CAN/CSA-C22.2 No 18-04, CAN/CSA-C22.2 No 25-1966, CAN/CSA-C22.2 No 30-M1986, CAN/CSA-C22.2 No.174-M1984, CAN/CSA-C22.2 No.94-M91, CAN/CSA-E60079-0:07, CAN/CSA-E60079-7:07, CAN/CSA-E60079-1:07, CAN/CSA-E61241-1-1, ANSI/UL 514B Edition 5, ANSI/UL 50 Edition 11, ANSI/UL 2225 Edition 4 |

| EAC Certificate (Formerly GOST R, K & B) | TC RU C-GB.AA87.B.00487 |

| UkrSEPRO | UA.TR.047.C.0644-15 |

| CCOE / PESO (India) Certificate | P333688 |

| RETIE Approval | 03866 |

| Marine Approvals | LRS: 01/00172, DNV: TAE00000Y, ABS: 15-LD1410479-PDA, BV: 43180/A1BV |

| Ingress Protection Rating** | NEMA 4X & IP66 |

| Cable Type | Corrugated & Interlocked Metal Clad Armour (MC) or TECK90, Continuously Welded Metal Clad Armour (MCHL), ACIC-HL, ACWU90-HL, RC90-HL, RA90-HL |

| Armour Clamping | 360° Stainless Steel Grounding Spring (non-magnetic) (berylium copper optional) |

| Jacket Sealing Technique | CMP Load Retention Seal |

| Sealing Area(s) | RapidEx Liquid Resin, Cable Outer Jacket |

| Cable Gland Material | Copper Free (<0.4%) Aluminium, Stainless Steel, Electroless Nickel Plated Brass |

Product Table

Metric

| Order Reference (NPT with RapidEx Resin) |

Entry Thread “C” | Minimum Thread Length “E” |

Cable Armor Diameter “A” | Cable Jacket Diameter “B” | Max Over Conductors “G” | Across Flats “D” | Across Corners “D” | Nominal Assembly Length “F” | Shroud | Approx Weight Aluminum (Kgs) |

|||||||

| Armor Stop In | Armor Stop Out | ||||||||||||||||

| Aluminum | Nickel Plated Brass | Stainless Steel | NPT | NPT Option | Min | Max | Min | Max | Min | Max | Max | Max | |||||

| TMC2X-050A075X | TMC2X-050NB075X | TMC2X-050SS075X | ½” | – | 19.8 | 10.7 | 14.0 | 14.0 | 16.0 | 12.7 | 19.1 | 13.0 | 30.5 | 33.5 | 62.0 | PVC06 | 0.06 |

| TMC2X-075A075X | TMC2X-075NB075X | TMC2X-075SS075X | – | ¾” | 20.3 | 10.7 | 14.0 | 14.0 | 16.0 | 13.0 | |||||||

| TMC2X-075A099X | TMC2X-075NB099X | TMC2X-075SS099X | ¾” | – | 20.3 | 15.2 | 16.5 | 16.5 | 22.6 | 17.5 | 25.1 | 18.0 | 37.6 | 41.4 | 75.2 | PVC09 | 0.09 |

| TMC2X-050A099X | TMC2X-050NB099X | TMC2X-050SS099X | – | ½” | 19.8 | 15.2 | 19.8 | 19.8 | 22.6 | 13.0 | |||||||

| TMC2X-100A118X | TMC2X-100NB118X | TMC2X-100SS118X | 1″ | – | 24.9 | 20.1 | 21.8 | 21.8 | 27.9 | 22.1 | 30.0 | 23.9 | 46.0 | 50.5 | 80.0 | PVC11 | 0.14 |

| TMC2X-075A118X | TMC2X-075NB118X | TMC2X-075SS118X | – | ¾” | 20.3 | 20.1 | 24.9 | 24.9 | 27.9 | 18.0 | |||||||

| TMC2X-125A137X | TMC2X-125NB137X | TMC2X-125SS137X | 1¼” | – | 25.4 | 23.9 | 27.4 | 27.4 | 32.5 | 25.9 | 34.8 | 30.5 | 52.1 | 57.4 | 90.2 | PVC15 | 0.19 |

| TMC2X-100A137X | TMC2X-100NB137X | TMC2X-100SS137X | – | 1″ | 24.9 | 23.9 | 30.0 | 30.0 | 32.5 | 23.9 | |||||||

| TMC2X-150A162X | TMC2X-150NB162X | TMC2X-150SS162X | 1½” | – | 26.2 | 31.0 | 34.3 | 34.3 | 38.1 | 33.0 | 41.1 | 37.1 | 59.9 | 66.0 | 91.2 | PVC18 | 0.25 |

| TMC2X-125A162X | TMC2X-125NB162X | TMC2X-125SS162X | – | 1¼” | 25.4 | 31.0 | 36.1 | 36.1 | 38.1 | 30.5 | |||||||

| TMC2X-150A190X | TMC2X-150NB190X | TMC2X-150SS190X | 1½” | – | 26.2 | – | – | 38.4 | 43.7 | 39.9 | 48.3 | 37.1 | 65.0 | 71.6 | 91.2 | PVC37 | 0.27 |

| TMC2X-125A190X | TMC2X-125NB190X | TMC2X-125SS190X | – | 1¼” | 25.4 | – | – | 38.4 | 43.7 | 30.5 | |||||||

| TMC2X-200A200X | TMC2X-200NB200X | TMC2X-200SS200X | 2″ | – | 38.9 | 39.9 | 43.2 | 43.2 | 47.8 | 41.9 | 50.8 | 41.4 | 69.9 | 77.0 | 95.5 | PVC21 | 0.31 |

| TMC2X-150A200X | TMC2X-150NB200X | TMC2X-150SS200X | – | 1½” | 26.2 | 39.9 | 43.2 | 43.2 | 47.8 | 37.1 | |||||||

| TMC2X-250A233X | TMC2X-250NB233X | TMC2X-250SS233X | 2½” | – | 41.4 | – | – | 46.0 | 56.1 | 48.5 | 59.2 | 54.1 | 74.9 | 82.6 | 100.8 | PVC28 | 0.36 |

| TMC2X-200A233X | TMC2X-200NB233X | TMC2X-200SS233X | – | 2″ | 38.9 | – | – | 46.0 | 56.1 | 48.3 | PVC23 | ||||||

| TMC2X-150A233X | TMC2X-150NB233X | TMC2X-150SS233X | – | 1½” | 26.2 | – | – | 46.0 | 56.1 | 37.1 | |||||||

| TMC2X-300A272X | TMC2X-300NB272X | TMC2X-300SS272X | 3″ | – | 41.4 | 54.4 | 62.5 | 55.1 | 66.3 | 57.7 | 69.1 | 64.8 | 89.9 | 98.8 | 104.1 | PVC31 | 0.70 |

| TMC2X-250A272X | TMC2X-250NB272X | TMC2X-250SS272X | – | 2½” | 41.4 | 54.4 | 62.5 | 62.5 | 66.3 | 54.1 | PVC28 | ||||||

| TMC2X-200A272X | TMC2X-200NB272X | TMC2X-200SS272X | – | 2″ | 38.9 | 54.4 | 62.5 | 62.5 | 66.3 | 48.3 | |||||||

| TMC2X-350A325X | TMC2X-350NB325X | TMC2X-350SS325X | 3½” | – | 42.7 | 63.2 | 70.6 | 70.6 | 75.4 | 66.5 | 82.6 | 75.7 | 110.0 | 120.9 | 118.6 | PVC32 | 1.21 |

| TMC2X-300A325X | TMC2X-300NB325X | TMC2X-300SS325X | – | 3″ | 41.4 | 63.2 | 70.6 | 70.6 | 75.4 | 75.7 | |||||||

| TMC2X-400A376X | TMC2X-400NB376X | TMC2X-400SS376X | 4″ | – | 43.9 | 74.9 | 87.6 | 87.6 | 89.9 | 80.3 | 95.5 | 85.9 | 122.9 | 135.1 | 125.7 | LSF33 | 1.51 |

| TMC2X-350A376X | TMC2X-350NB376X | TMC2X-350SS376X | – | 3½” | 42.7 | 74.9 | 87.6 | 87.6 | 89.9 | 85.9 | |||||||

| TMC2X-400A425X | TMC2X-400NB425X | TMC2X-400SS425X | 4″ | – | 43.9 | – | – | 90.4 | 100.1 | 94.0 | 108.0 | 85.9 | 132.8 | 146.1 | 131.1 | LSF34 | 1.68 |

| Dimensions in millimeters unless otherwise stated | |||||||||||||||||

Imperial

| Order Reference (NPT with RapidEx Resin) |

Entry Thread “C” | Minimum Thread Length “E” |

Cable Armor Diameter “A” | Cable Jacket Diameter “B” | Max Over Conductors “G” | Across Flats “D” | Across Corners “D” | Nominal Assembly Length “F” | Shroud | Approx Weight Aluminum (Ozs) |

|||||||

| Armor Stop In | Armor Stop Out | ||||||||||||||||

| Aluminum | Nickel Plated Brass | Stainless Steel | NPT | NPT Option | Min | Max | Min | Max | Min | Max | Max | Max | |||||

| TMC2X-050A075X | TMC2X-050NB075X | TMC2X-050SS075X | ½” | – | 0.78 | 0.42 | 0.55 | 0.55 | 0.63 | 0.500 | 0.750 | 0.51 | 1.20 | 1.32 | 2.44 | PVC06 | 2.29 |

| TMC2X-075A075X | TMC2X-075NB075X | TMC2X-075SS075X | – | ¾” | 0.80 | 0.42 | 0.55 | 0.55 | 0.63 | 0.51 | |||||||

| TMC2X-075A099X | TMC2X-075NB099X | TMC2X-075SS099X | ¾” | – | 0.80 | 0.60 | 0.65 | 0.65 | 0.89 | 0.690 | 0.990 | 0.71 | 1.48 | 1.63 | 2.96 | PVC09 | 3.00 |

| TMC2X-050A099X | TMC2X-050NB099X | TMC2X-050SS099X | – | ½” | 0.78 | 0.60 | 0.78 | 0.78 | 0.89 | 0.51 | |||||||

| TMC2X-100A118X | TMC2X-100NB118X | TMC2X-100SS118X | 1″ | – | 0.98 | 0.79 | 0.86 | 0.86 | 1.10 | 0.870 | 1.180 | 0.94 | 1.81 | 1.99 | 3.15 | PVC11 | 5.11 |

| TMC2X-075A118X | TMC2X-075NB118X | TMC2X-075SS118X | – | ¾” | 0.80 | 0.79 | 0.98 | 0.98 | 1.10 | 0.71 | |||||||

| TMC2X-125A137X | TMC2X-125NB137X | TMC2X-125SS137X | 1¼” | – | 1.00 | 0.94 | 1.08 | 1.08 | 1.28 | 1.020 | 1.370 | 1.20 | 2.05 | 2.26 | 3.55 | PVC15 | 6.70 |

| TMC2X-100A137X | TMC2X-100NB137X | TMC2X-100SS137X | – | 1″ | 0.98 | 0.94 | 1.18 | 1.18 | 1.28 | 0.94 | |||||||

| TMC2X-150A162X | TMC2X-150NB162X | TMC2X-150SS162X | 1½” | – | 1.03 | 1.22 | 1.35 | 1.35 | 1.50 | 1.300 | 1.620 | 1.46 | 2.36 | 2.60 | 3.59 | PVC18 | 8.82 |

| TMC2X-125A162X | TMC2X-125NB162X | TMC2X-125SS162X | – | 1¼” | 1.00 | 1.22 | 1.42 | 1.42 | 1.50 | 1.20 | |||||||

| TMC2X-150A190X | TMC2X-150NB190X | TMC2X-150SS190X | 1½” | – | 1.03 | – | – | 1.51 | 1.72 | 1.570 | 1.900 | 1.46 | 2.56 | 2.82 | 3.59 | PVC37 | 9.45 |

| TMC2X-125A190X | TMC2X-125NB190X | TMC2X-125SS190X | – | 1¼” | 1.00 | – | – | 1.51 | 1.72 | 1.20 | |||||||

| TMC2X-200A200X | TMC2X-200NB200X | TMC2X-200SS200X | 2″ | – | 1.53 | 1.57 | 1.70 | 1.70 | 1.88 | 1.650 | 2.000 | 1.63 | 2.75 | 3.03 | 3.76 | PVC21 | 11.06 |

| TMC2X-150A200X | TMC2X-150NB200X | TMC2X-150SS200X | – | 1½” | 1.03 | 1.57 | 1.70 | 1.70 | 1.88 | 1.46 | |||||||

| TMC2X-250A233X | TMC2X-250NB233X | TMC2X-250SS233X | 2½” | – | 1.63 | – | – | 1.81 | 2.21 | 1.910 | 2.330 | 2.13 | 2.95 | 3.25 | 3.97 | PVC28 | 12.77 |

| TMC2X-200A233X | TMC2X-200NB233X | TMC2X-200SS233X | – | 2″ | 1.53 | – | – | 1.81 | 2.21 | 1.90 | PVC23 | ||||||

| TMC2X-150A233X | TMC2X-150NB233X | TMC2X-150SS233X | – | 1½” | 1.03 | – | – | 1.81 | 2.21 | 1.46 | |||||||

| TMC2X-300A272X | TMC2X-300NB272X | TMC2X-300SS272X | 3″ | – | 1.63 | 2.14 | 2.46 | 2.17 | 2.61 | 2.270 | 2.720 | 2.55 | 3.54 | 3.89 | 4.10 | PVC31 | 24.69 |

| TMC2X-250A272X | TMC2X-250NB272X | TMC2X-250SS272X | – | 2½” | 1.63 | 2.14 | 2.46 | 2.46 | 2.61 | 2.13 | PVC28 | ||||||

| TMC2X-200A272X | TMC2X-200NB272X | TMC2X-200SS272X | – | 2″ | 1.53 | 2.14 | 2.46 | 2.46 | 2.61 | 1.90 | |||||||

| TMC2X-350A325X | TMC2X-350NB325X | TMC2X-350SS325X | 3½” | – | 1.68 | 2.49 | 2.78 | 2.78 | 2.97 | 2.620 | 3.250 | 2.98 | 4.33 | 4.76 | 4.67 | PVC32 | 42.68 |

| TMC2X-300A325X | TMC2X-300NB325X | TMC2X-300SS325X | – | 3″ | 1.63 | 2.49 | 2.78 | 2.78 | 2.97 | 2.98 | |||||||

| TMC2X-400A376X | TMC2X-400NB376X | TMC2X-400SS376X | 4″ | – | 1.73 | 2.95 | 3.45 | 3.45 | 3.54 | 3.160 | 3.760 | 3.38 | 4.84 | 5.32 | 4.95 | LSF33 | 53.44 |

| TMC2X-350A376X | TMC2X-350NB376X | TMC2X-350SS376X | – | 3½” | 1.68 | 2.95 | 3.45 | 3.45 | 3.54 | 3.38 | |||||||

| TMC2X-400A425X | TMC2X-400NB425X | TMC2X-400SS425X | 4″ | – | 1.73 | – | – | 3.56 | 3.94 | 3.700 | 4.250 | 3.38 | 5.23 | 5.75 | 5.16 | LSF34 | 59.19 |

| Dimensions displayed in millimeters unless otherwise stated | |||||||||||||||||