ATEX & IECEx Zones & Equipment

ATEX & IECEx Zones & Equipment

An atmosphere can become potentially explosive when it contains dangerous levels of flammable gases, mists or dusts.

If a source of ignition is then introduced, combustion can occur.

The risk of explosion can be reduced by preventing the release or build-up of flammable substances and by eliminating sources of ignition.

However first we need to understand if or how long an explosive atmosphere could be present.

This is where zones are introduced and in general this is based on historical information as per;

Zone (Gas) | Zone (Dust) | Definition | 0 | 20 | >1000 hours per year |

|---|---|---|

1 | 21 | Between 10 & 1000 hours per year |

2 | 22 | <10 hours per year |

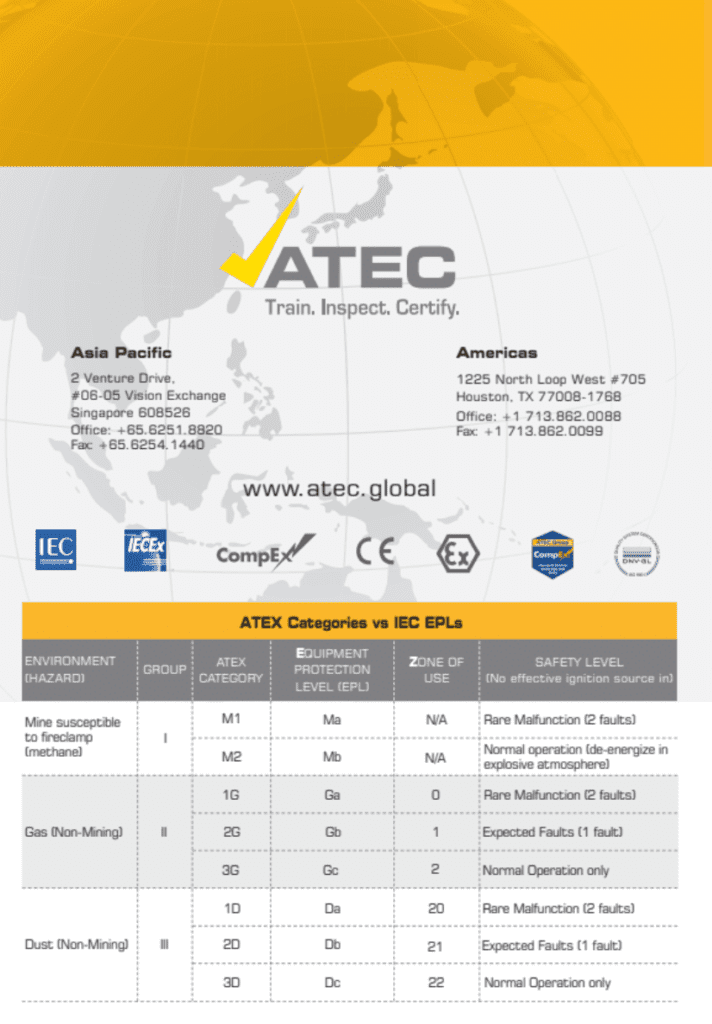

The following table shows Zones in relation to ATEX safety categories that equipment is required to meet to ensure the correct level of protection is applied within a potentially explosive atmosphere;

Zone (Gas) | Zone (Dust) | Danger / Protection Level | ATEX Safety Category Required* | Zone 0 | Zone 20 | Constant danger/Very high.

Explosive hazard always present. | Category 1 equipment. |

|---|---|---|---|

Zone 1 | Zone 21 | Potential danger/high.

Explosive hazard occasionally present during normal working practices.

| Minimum of Category 2 equipment. |

Zone 2 | Zone 22 | Minor danger/normal.

Explosive hazard not likely or only for short periods | Minimum of Category 3 equipment. |

Zone (Gas) | Zone (Dust) | Definition | Equipment Protection Level (EPL) Required* | Zone 0 | Zone 20 | Constant danger/Very high.

Explosive hazard always present. | Ga / Da |

|---|---|---|---|

Zone 1 | Zone 21 | Potential danger/high.

Explosive hazard occasionally present during normal working practices. | Gb / Db |

Zone 2 | Zone 22 | Minor danger/normal.

Explosive hazard not likely or only for short periods | Gc / Dc |

Equipment Temperature Class | Maximum surface temperature °C | Suitable in Area with “T Class” | T1 | 450 | T1 only |

|---|---|---|

T2 | 300 | T1 – T2 |

T3 | 200 | T1 – T3 |

T4 | 135 | T1 – T4 |

T5 | 100 | T1 – T5 |

T6 | 85 | T1 – T6 |

The following table shows Gas Sub Groups for surface industries, their example/typical substance in relation to which “gas areas” they are suitable for use;

Equipment Gas Group | Typical Substances | Suitable in Area with “Gas Group” | IIC | Acetylene & Hydrogen | IIC, IIB & IIA |

|---|---|---|

IIB | Ethylene | IIB & IIA |

IIA | Propane | IIA ONLY |

Americas

1225 North Loop West, Suite #705 Houston, TX 77008 Office: 713.862.0088 Fax: 832.358.1165

UAE

India

Myanmar

Thailand